Chevrolet Cruze Repair Manual: Interior Lamps Dimming

This group includes lamps which may dim. This group may use a combination of vacuum fluorescent illumination, LEDs and incandescent lamps

- HVAC control module, head assembly

- Rear HVAC control module, head assembly

- Radio

- Rear seat audio

- The instrument panel cluster

- The PRNDL lamp, with the exception of the current gear select position

- Power window switches

- Various switches

When the ignition switch is turned to the ON position, the vacuum fluorescent display, radio, turns ON at maximum brightness. When the park lamps are ON, all incandescent back lighting turn ON at the dimming level indicated by the instrument panel cluster dimmer switch.

At the same time all fluorescent display displays dim to match the indicated dimming level. When the headlamp switch is placed in the PARK position, the park lamp supply voltage circuit provides an input to the BCM. The BCM then supplies voltage to the instrument panel cluster dimmer switch through the dimming control circuit. The setting of the instrument panel cluster dimmer switch determines the amount of voltage that the instrument panel cluster dimmer switch supplies to the BCM through the instrument panel cluster dimming lamps low reference circuit. The BCM then sends a PWM voltage to all the interior lamps. All the fluorescent display and incandescent back lighting lamps are provided a specific voltage and are then grounded. When the headlight switch is turned to the park lamp or headlamp position, all incandescent back lighting turn ON at the dimming level indicated by the instrument panel cluster dimmer switch. When the instrument panel cluster dimmer switch is moved from MIN to MAX, all fluorescent display displays, as well as all incandescent back lighting respond from minimum intensity to maximum brightness in response to the instrument panel cluster dimmer switch.

Inadvertent Power

The BCM used in this vehicle controls the lighting system through circuits that enable the interior lamps. The BCM opens these enabling circuits shortly after the ignition switch is turned OFF with no lamp switch activity. If the ignition switch is turned to any position other than OFF, or if a lamp switch is activated during this period, the timer will reset itself.

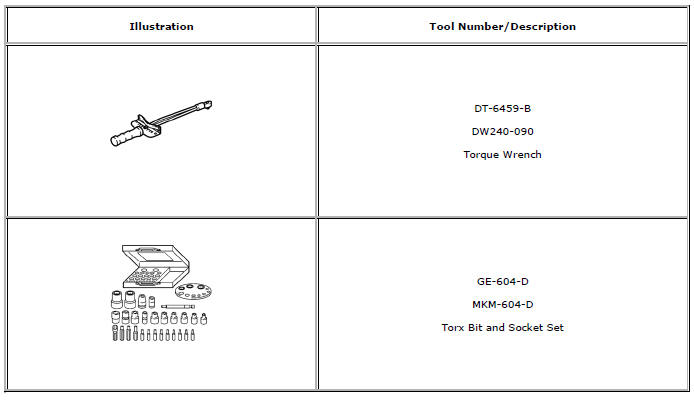

Special Tools and Equipment

Courtesy/Illuminated Entry Lamps

Courtesy/Illuminated Entry Lamps

The following lamps may be manually turned ON by placing the interior lamp

switch in the ON position, or by opening a door while the

switch is in the AUTO position.

The dome lamp

The liftgate ...

Mirrors

Mirrors

Specifications

Inside Rearview Mirror Schematics

Outside Rearview Mirror Schematics

Outside Rearview Mirror Replacement

Preliminary Procedure

Remove the front side door tri ...

Other materials:

Removal Procedure

Warning: Refer to Approved Equipment for Collision Repair Warning in the

Preface section.

Warning: Refer to Collision Sectioning Warning in the Preface section.

Warning: Refer to Glass and Sheet Metal Handling Warning in the Preface section.

Disable the SIR System. Refer to SIR

...

Winter Tires

This vehicle was not, originally, equipped with winter tires. Winter tires are

designed for increased traction on snow and ice-covered roads. Consider installing

winter tires on the vehicle if frequent driving on snow or ice-covered roads is

expected. See your dealer for details regarding wint ...

Lifting and Jacking the Vehicle

Note: The use of a LOW PROFILE LIFT ARMS SYSTEM may be required to

avoid unwanted contact with the vehicle's body and structure

depending on lifting equipment used. Refer to the manufacture's recommendation

for their applications of low profile lift arms system for

their lifting equipment.

...