Chevrolet Cruze Repair Manual: Thread Repair

General purpose thread repair kits are available commercially.

Warning: Refer to Safety Glasses Warning in the Preface section.

Note: Refer to the thread repair kit manufacturer's instructions regarding the size of the drill and which tap to use.

Always avoid any buildup of chips. Back out the tap every few turns and remove the chips.

- Determine the size, the pitch, and the depth of the damaged thread.

- Adjust the stop collars on the cutting tool as needed. Tap the stop collars to the required depth.

- Drill out the damaged thread.

- Remove the chips.

- Apply clean engine oil to the top thread.

- Use the tap in order to cut new thread.

- Clean the thread.

- Screw the thread insert onto the mandrel of the thread insert installer. Engage the tang of the thread insert onto the end of the mandrel.

Note: The thread insert should be flush to 1 turn below the surface.

- Lubricate the thread insert with clean engine oil - except when installing in aluminum - and install the thread insert.

- If the tang of the thread insert does not break off when backing out the thread insert installer, break off the tang using a drift punch.

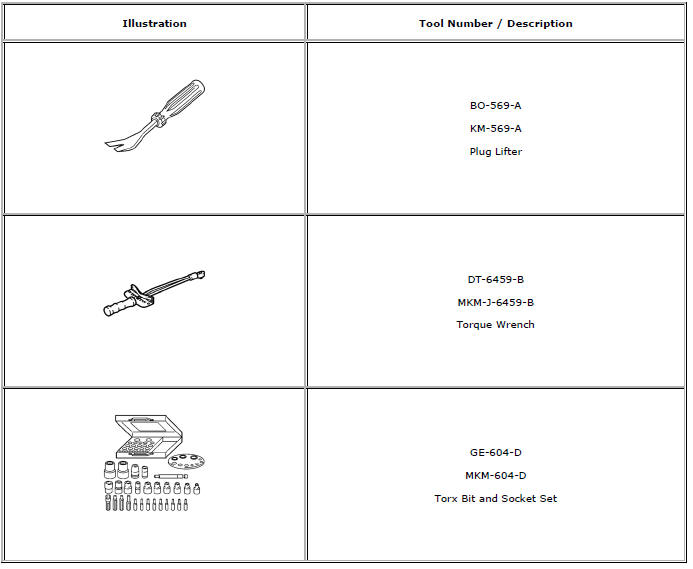

Special Tools and Equipment

Rear Seat Back Cushion Cover and Pad Replacement - Left Side

Rear Seat Back Cushion Cover and Pad Replacement - Left Side

Preliminary Procedure

Remove rear seat - left side. Refer to Rear Seat Replacement

Rear Seat Back Cushion Cover

Procedure

Remove the staples from the seat back cover.

Remove seat ba ...

Seat Heating and Cooling

Seat Heating and Cooling

Specifications

Heated/Cooled Seat Schematics

Front Seat Heater Control Module Replacement

Preliminary Procedure

Driver or passenger seat replacement. Refer to Driver or Passenger S ...

Other materials:

Front End Inflatable Restraint Discriminating Sensor Replacement

Warning: Refer to SIR Warning in the Preface section.

Warning: Following the deployment of a side impact air bag, inspect the

following parts for damage. Replace these parts if

necessary:

The seat cushion frame

The seat recliner, if equipped

The seat adjuster

The seat back frame

...

Bumpers and Fascias

Specifications

Front Bumper Energy Absorber Replacement

Preliminary Procedure

Remove the front bumper fascia. Refer to Front Bumper Fascia Replacement.

Front Bumper Energy Absorber

Procedure

Unclip from front bumper fascia. ...

Environmental Fallout (Acid Rain)

Caution: Refer to Clearcoat/Ultraviolet Screeners Caution in the

Preface section.

Note: Always refer to the manufacturer's packaged instructions for

the detailed procedures of materials used for compounding and/or

polishing.

Since the severity of the condition varies from area to area, proper ...