Chevrolet Cruze Repair Manual: Frame and Underbody

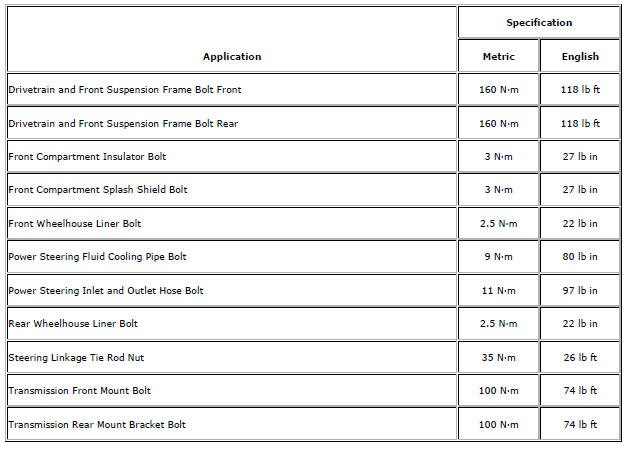

Specifications

Engine Shield Replacement

Preliminary Procedure

Raise and support the vehicle. Refer to Lifting and Jacking the Vehicle.

- Engine Shield Bolt (Qty: 4)

Caution: Refer to Fastener Caution in the Preface section.

Tighten 40 N·m (30 lb ft)

- Engine Shield

Front Compartment Insulator Replacement

Preliminary Procedure

Raise and support the vehicle. Refer to Lifting and Jacking the Vehicle.

- Front Compartment Insulator Screw (Qty: 8)

Caution: Refer to Fastener Caution in the Preface section.

Tighten 3 N·m (3 lb in)

- Front Compartment Insulator Plastic Retainer (Qty: 3)

- Front Compartment Insulator

Front Compartment Splash Shield Replacement

- Front Compartment Splash Shield Retainer (Qty: 2)

- Front Compartment Splash Shield Bolt (Qty: 3)

Caution: Refer to Fastener Caution in the Preface section.

Tighten 3 N·m (27 lb in)

- Front Compartment Splash Shield

- Drivetrain and Front Suspension Frame Replacement

- Drivetrain and Front Suspension Frame Insulator Replacement

Ultra High Strength Dual Phase Steel

Ultra High Strength Dual Phase Steel

This information provides repair recommendations and general guidelines for

steel classified as Ultra High Strength Dual Phase Steel (Dual

Phase Steel with a tensile strength greater than 800 MPa), ...

Drivetrain and Front Suspension Frame Replacement

Drivetrain and Front Suspension Frame Replacement

Special Tools

CH 904 Underframe

CH 49289 Centering Adapter

For equivalent regional tools, refer to Special Tools. ...

Other materials:

Engine Compartment Overview

1.4L L4 Engine

1. Engine Air Cleaner/Filter

2. Engine Oil Dipstick.

3. Engine Cooling Fan (Out of View).

4. Engine Oil Fill Cap.

5. Remote Negative (-) Grounding Point.

6. Brake/Clutch Fluid Reservoir.

7. Battery

8. Engine Coolant Surge Tank and Pressure Cap.

9. Remote Positive (+ ...

If the Vehicle Is Stuck

Slowly and cautiously spin the wheels to free the vehicle when stuck in sand,

mud, ice, or snow.

If stuck too severely for the traction system to free the vehicle, turn the traction

system off and use the rocking method.

WARNING

If the vehicle's tires spin at high speed, they can explode, ...

Radio Reception

Frequency interference and static can occur during normal radio reception if

items such as phone chargers, vehicle convenience accessories, and external electronic

devices are plugged into the accessory power outlet. If there is interference or

static, unplug the item from the accessory power ...