Chevrolet Cruze Repair Manual: Variable Effort Steering System Description and Operation

The Variable Effort Steering (VES) system or MAGNASTEER® varies the amount of effort required to steer the vehicle as vehicle speed changes. At low speeds, the system provides minimal steering effort for easy turning and parking maneuvers. Steering effort is increased at higher speeds to provide firmer steering (road feel) and directional stability. VES works in parallel with the base torsion bar in the power steering system.

The VES control module communicates on the high speed bus and uses vehicle speed and the steering wheel angle speed to command a current that is most appropriate for each speed to the VES actuator in the steering rack and pinion. The actuator is a variable electromagnetic actuator, which consists of one multiple-pole ring-style permanent magnet, with a pole piece, and an electromagnetic coil assembly on each side. By commanding currents between -3 to +3 Amps through the coils the steering effort will be adapted to the vehicle’s speed.

At lowest speed, around 5 km/h (3 mph) the coils are polarized in such a way that the magnetic forces are repelling each others and hardly any effort is required to turn the ring magnet between them.

At mid speed, around 70 km/h (45 mph), no current is sent through the coils and steering is assisted by hydraulics only. At high speeds the coils are polarized in such a way that the magnetic forces are attracting each others and high effort is required to turn the ring magnet between them.

The VES control module communicates on the HS GMLAN bus.

The VES control module has the ability to detect malfunctions in the actuator. Any malfunctions detected will cause the system to ramp to zero amps. Steering will be assisted by hydraulics only and a DTC is set.

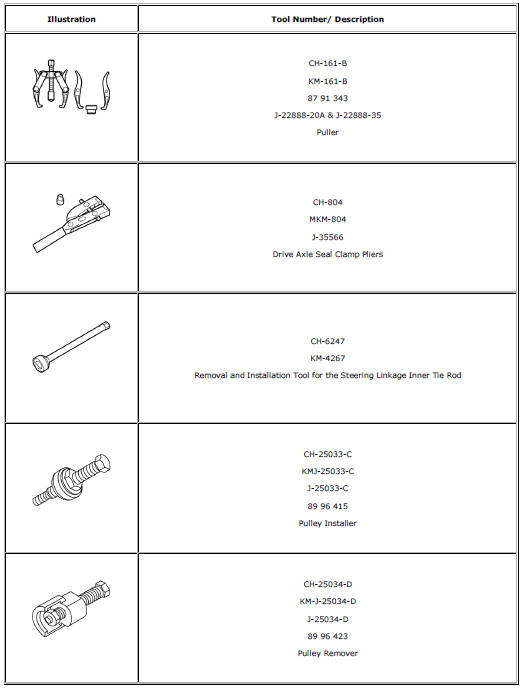

Special Tools and Equipment

Power Steering System Description and Operation

Power Steering System Description and Operation

The hydraulic power steering pump is a constant displacement vane-type pump

that provides hydraulic pressure and flow for the power

steering gear. The hydraulic power steering pumps are either belt ...

Steering Wheel and Column

Steering Wheel and Column

Specifications

...

Other materials:

Headlamps, Front Turn Signal and Parking Lamps

1. Parking/Turn Signal Lamp

2. High-Beam Headlamp/ Low-Beam Headlamp and DRL

High-Beam Headlamp/ Low-Beam Headlamp and DRL

1. Open the hood

2. For the driver side bulb, remove the windshield washer bottle filler neck by

firmly pulling it straight up and out of the bottle.

3. Remove the co ...

Infants and Young Children

Everyone in a vehicle needs protection! This includes infants and all other children.

Neither the distance traveled nor the age and size of the traveler changes the need,

for everyone, to use safety restraints. In fact, the law in every state in the United

States and in every Canadian province ...

Driver Seat Frame Replacement

Removal Procedure

Remove front seat cushion cover (1) and pad (2) from frame (3). Refer to

Front Seat Cushion Cover and Pad Replacement

Remove the wire harness (1), if equipped.

Remove front seat back cushion cover (1) and pad (2) from frame (3).

Refer to Driver or ...