Chevrolet Cruze Repair Manual: Seat Heating and Cooling

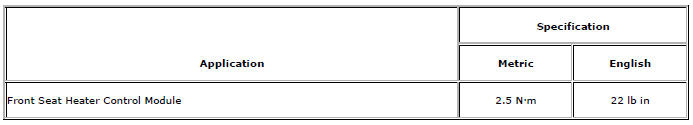

Specifications

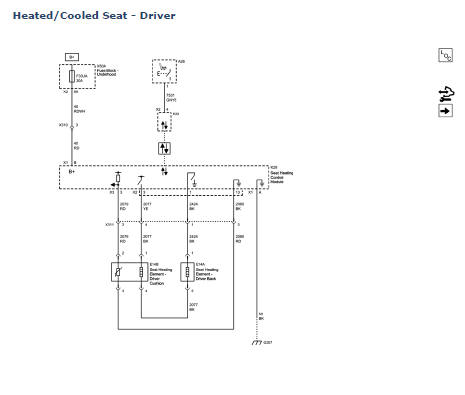

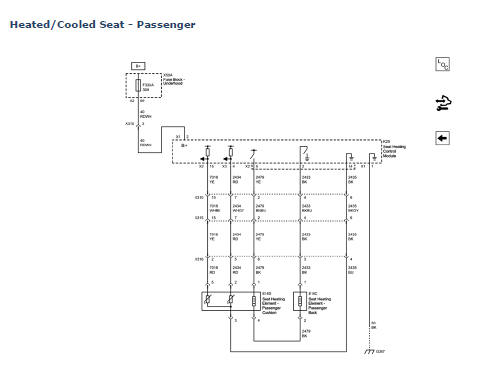

Heated/Cooled Seat Schematics

Front Seat Heater Control Module Replacement

Preliminary Procedure

Driver or passenger seat replacement. Refer to Driver or Passenger Seat Replacement.

Front Seat Heater Control Module Bolt (Qty: 2)

Caution: Refer to Fastener Caution in the Preface section.

Tighten 2.5 N·m (23 lb in)

Front Seat Heater Control Module

Procedure

Disconnect the electrical connector.

Driver or Passenger Seat Back Cushion Heater Replacement

Preliminary Procedure

Front seat back cushion cover and cushion pad replacement. Refer to Front Seat Back Cushion Cover and Cushion Pad Replacement

- Front Seat Back Heater

Driver Seat Cushion Heater Replacement

Preliminary Procedure

Front seat cushion cover and pad replacement. Refer to Front Seat Cushion Cover and Pad Replacement.

- Front Seat Heater

Passenger Seat Cushion Heater Replacement

Preliminary Procedure

Front seat cushion cover and pad replacement. Refer to Front Seat Cushion Cover and Pad Replacement.

Front Seat Heater

Heated Seats Description and Operation

Heated Seat Components

The driver and passenger heated seats consist of the following components:

- Left heated seat switch

- Right heated seat switch

- HVAC control

- Seat heating control module

- Driver seat cushion heating element

- Driver seat back heating element

- Driver seat cushion temperature sensor

- Passenger seat cushion heating element

- Passenger seat back heating element

- Passenger seat cushion temperature sensor

Power and Ground

Battery positive voltage is supplied at all times to the seat heating control module through a 30 A fuse located in the underhood fuse block.

This voltage is used by the module to supply power to the seat heating elements. Ground for the module is provided at G307.

Heated Seat Operation

The driver and passenger heated seats are controlled by a single seat heating control module that is located under the driver seat cushion.

Both heated seats are controlled by separate heated seat switches that are located in the HVAC control. When a heated seat switch is pressed, a serial data message is sent from the HVAC control to the HVAC control module indicating the heated seat command. The HVAC control module then serves as a gateway to transmit the message to the seat heating control module via the serial data line. In response to this signal, the seat heating control module applies battery positive voltage through the element supply voltage circuit to the appropriate seat heating elements. The seat heating control module then sends a serial data message back to the HVAC control module to gateway the information to the HVAC control to either illuminate or turn off the appropriate temperature indicator.

Temperature Regulation

When the engine ON, the heated seats will initialize in the OFF state. With each activation of the heated seat switch, the seat heating control module will cycle the temperature setting in the following manner: HIGH, MEDIUM, LOW, and OFF.

The seat heating control module monitors the seat temperature through the temperature sensor signal circuit and the temperature sensor (thermistor) that is located in the seat cushion. The temperature sensor is a variable resistor, it's resistance changes as the temperature of the seat changes. When the temperature sensor resistance indicates to the seat heating control module that the seat has reached the desired temperature, the module opens the ground path of the seat heating elements through the heated seat element control circuit. The module will then cycle the element control circuit open and closed in order to maintain the desired temperature.

Load Management

electrical power management function is designed to monitor the vehicle electrical load and determine when the battery is potentially in a high discharge condition. The heated seat system is one of the vehicle loads that is subject to reduction during a battery discharge condition. For more information on load management refer to Electrical Power Management Description and Operation.

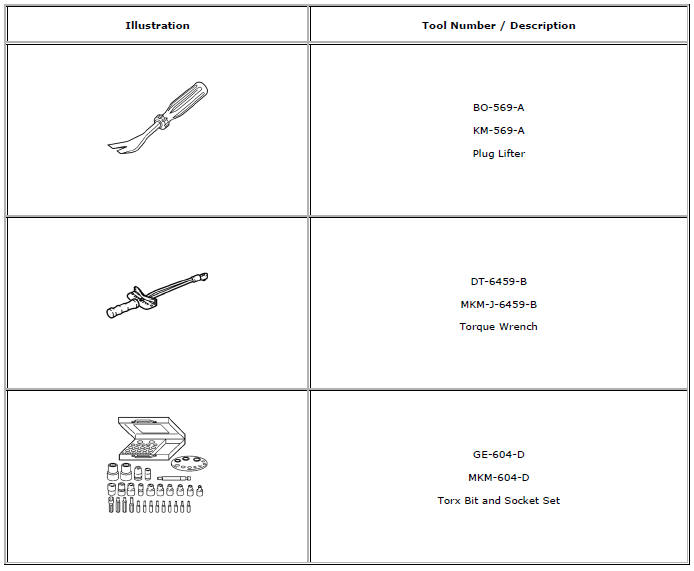

Special Tools and Equipment

Thread Repair

Thread Repair

General purpose thread repair kits are available commercially.

Warning: Refer to Safety Glasses Warning in the Preface section.

Note: Refer to the thread repair kit manufacturer's instructions

...

Restraints

Restraints

Specifications

Module Power, Ground, and MIL

Front Impact Sensor, Retractors, and Driver/Passenger Air

Bags

Side Impact Sensors and Side/Roof Air Bags

Air Bag Indicator and Disab ...

Other materials:

Inflatable Restraint Roof Rail Modules

The roof rail modules are located under the headliner extending from the

front windshield pillar to the rear window pillar. The roof rail

modules contain a housing, inflatable air bag, initiating device, and a canister

of gas generating material. The initiator is part of the roof

rail module d ...

Installation Procedure

Align the rear compartment floor panel.

Drill 4 mm (3/16 in) for rivets along the edges of the rear compartment

floor were you cant apply a resistance spot welder.

Clean and prepare the attaching surfaces for

spot welding and riveting.

Apply structural adhesive to all a ...

Taillamps, Turn Signal, Sidemarker, Stoplamps, and Back-Up Lamps

Trunk Deck Inboard Taillamps

1. Open the trunk.

2. Remove the trunk deck trim cover (1).

3. Remove the bulb socket (2) by turning counterclockwise and pulling straight out.

4. Remove the bulb from the socket.

5. Install the new bulb in the bulb socket.

6. Install the bulb socket by turni ...