Chevrolet Cruze Repair Manual: Thread Inserts

General Purpose Thread Repair Kits.

These kits are available commercially.

Repair Procedure

Warning: Refer to Safety Glasses Warning in the Preface section.

Note: Refer to the thread repair kit manufacturer's instructions regarding the size of the drill and tap to use. Avoid any buildup of chips. Back out the tap every few turns and remove the chips.

- Determine the size, the pitch, and the depth of the damaged thread. If necessary, adjust the stop collars on the cutting tool and tap to the required depth.

- Drill out the damaged threads. Clean out any chips.

- Lubricate the tap with light engine oil. Tap the hole. Clean the threads.

- Thread the thread insert onto the mandrel of the installer. Engage the tang of the insert onto the end of the mandrel.

Note: The insert should be flush to one turn below the surface.

- Lubricate the insert with light engine oil, except when installing in aluminum and install the insert.

- If the tang of the insert does not break off when backing out the installer, break the tang off with a drift.

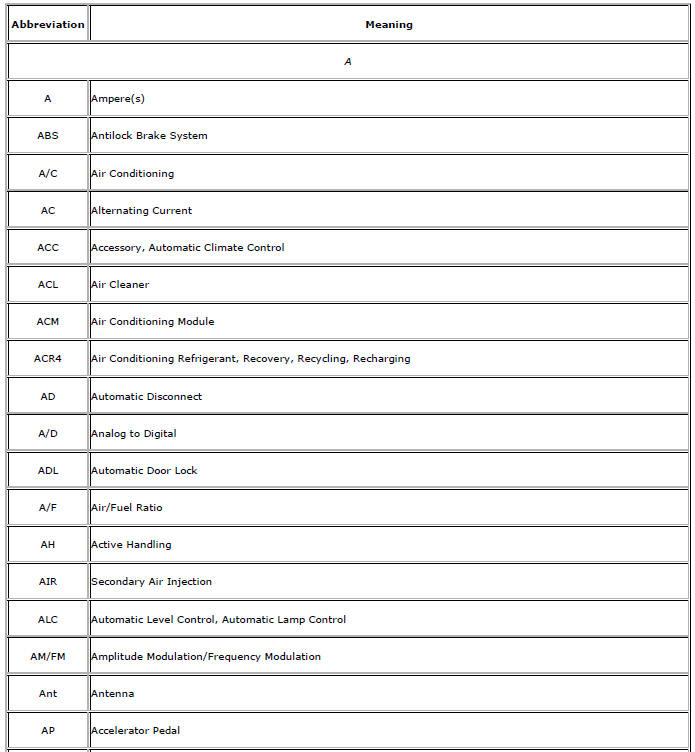

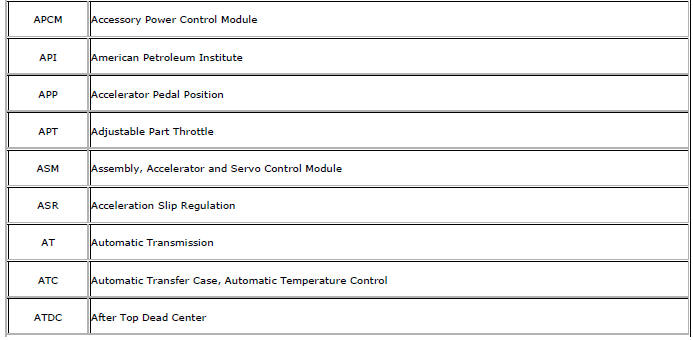

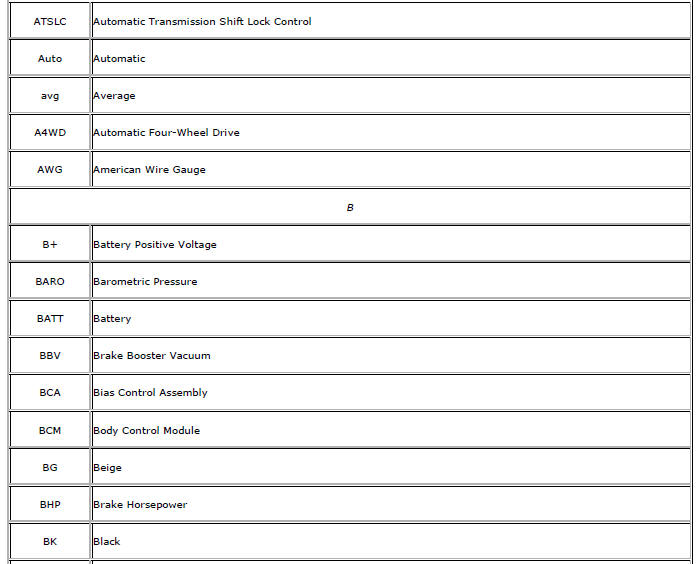

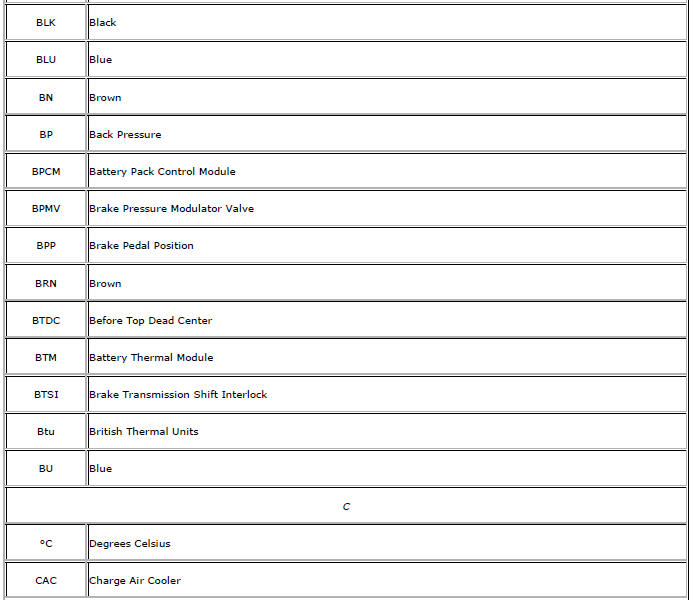

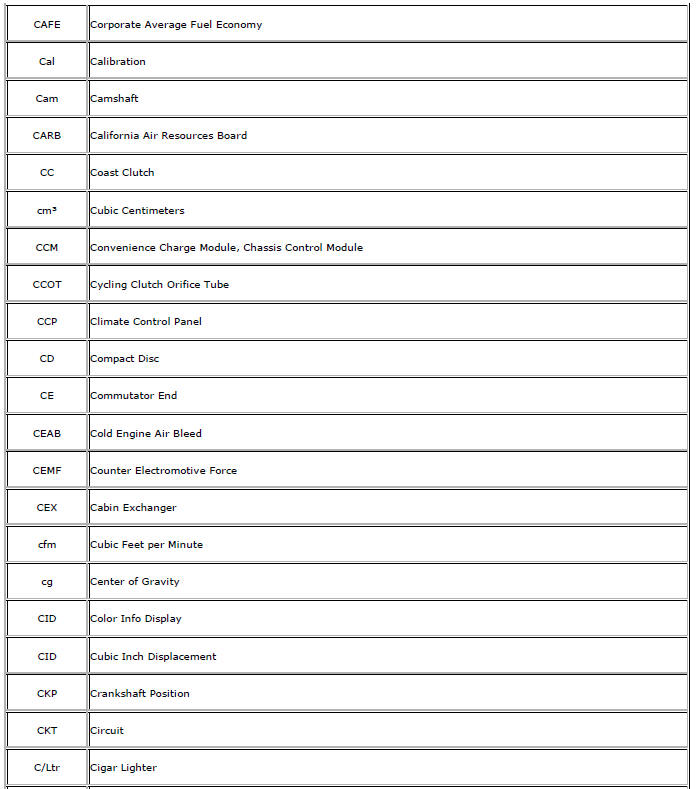

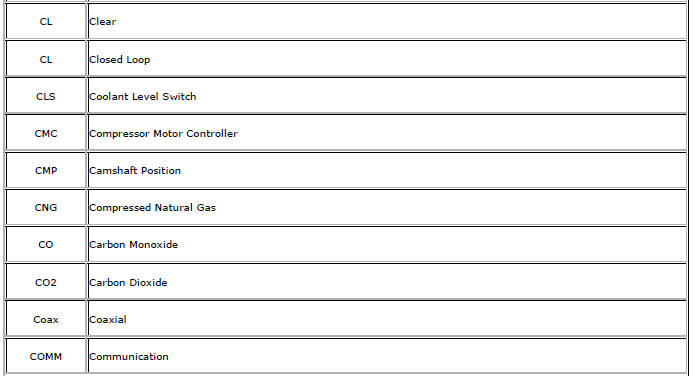

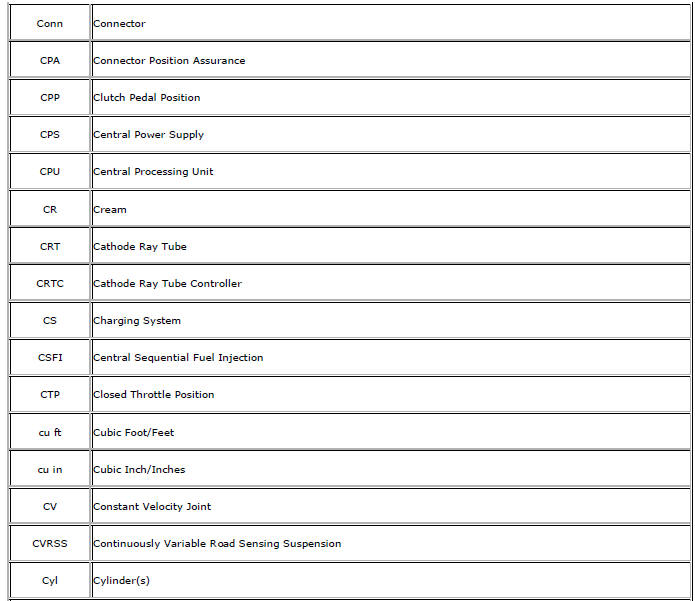

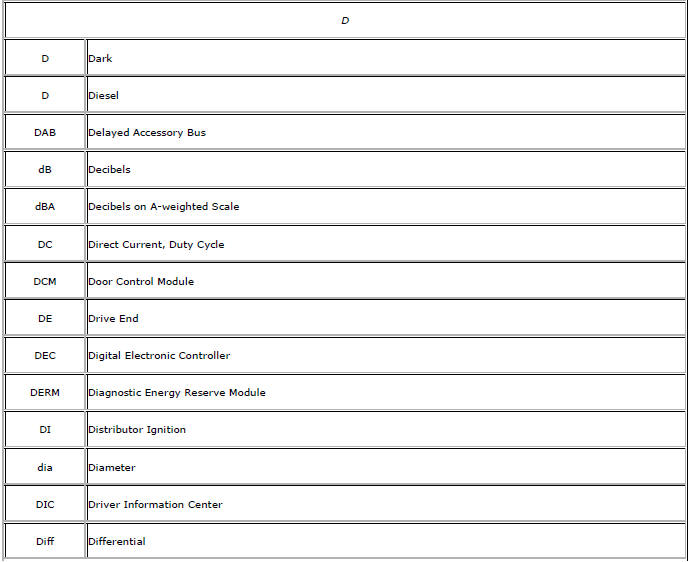

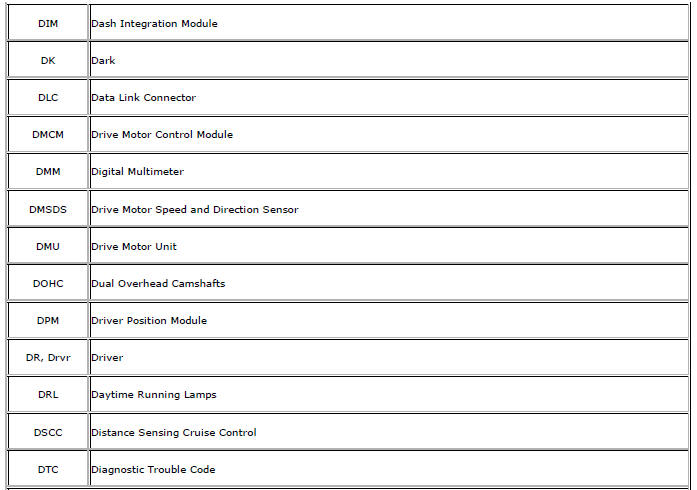

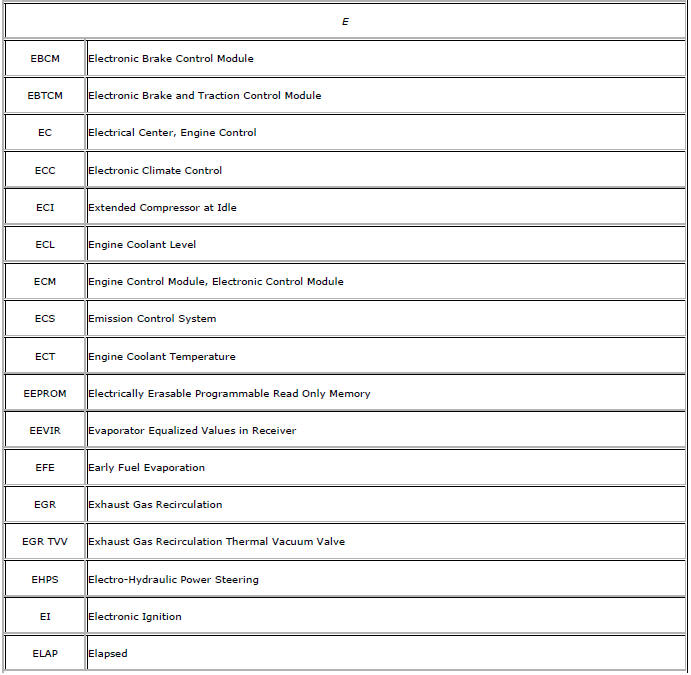

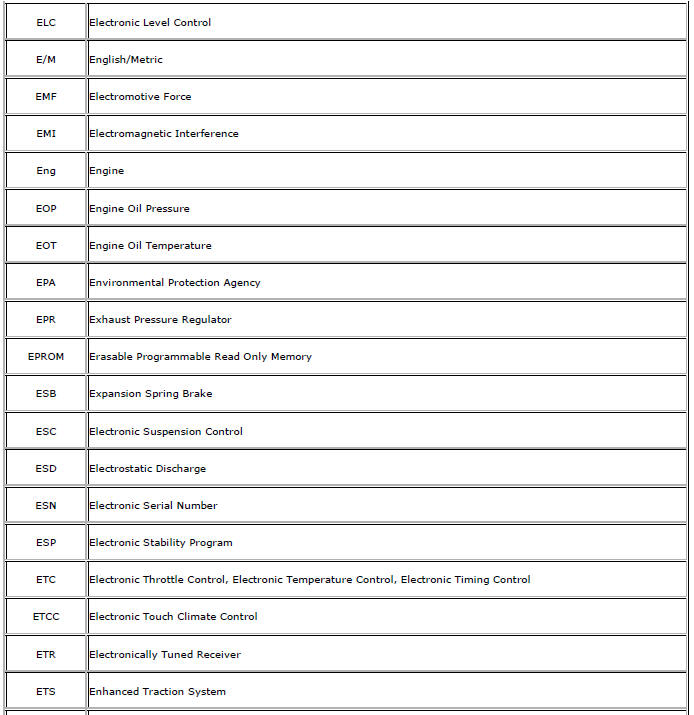

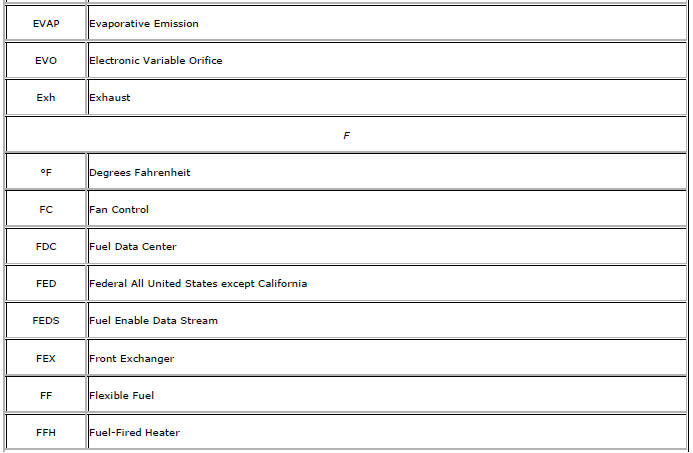

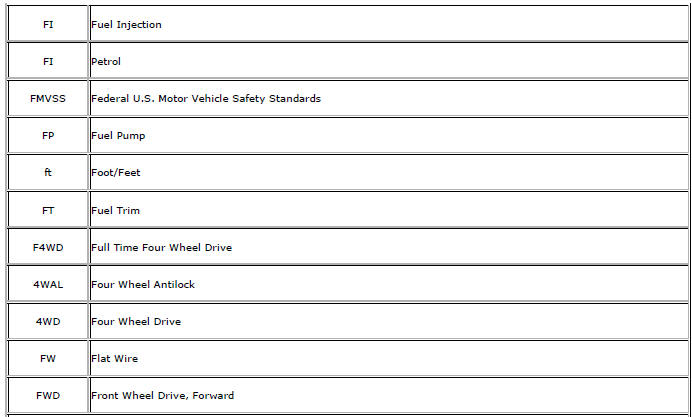

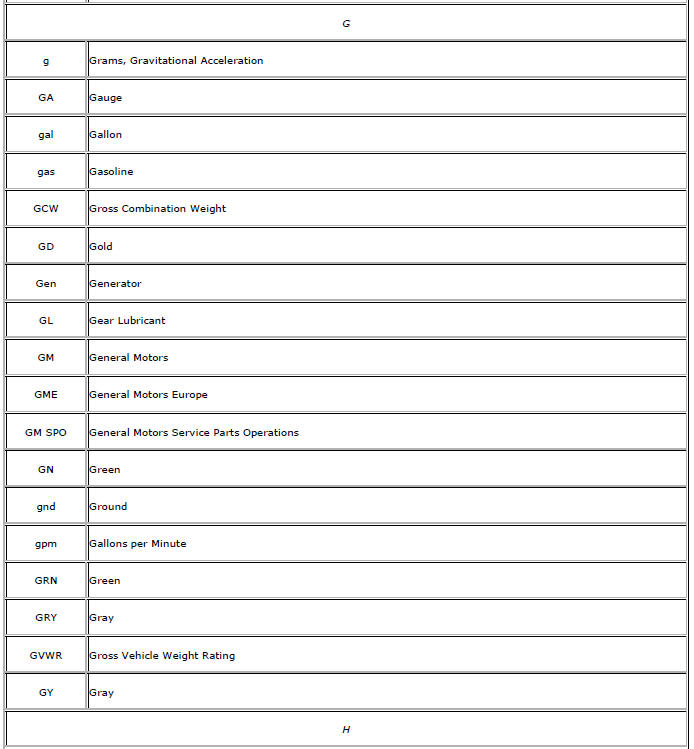

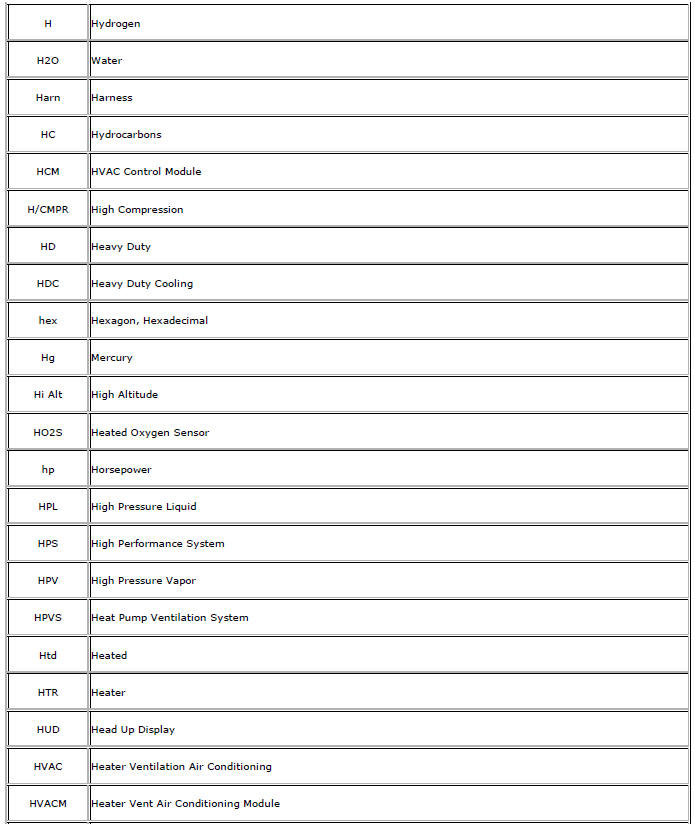

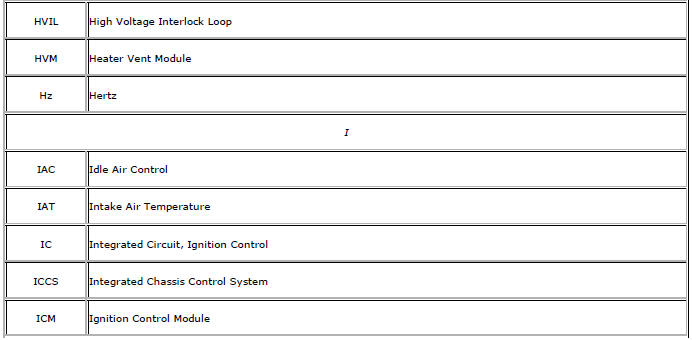

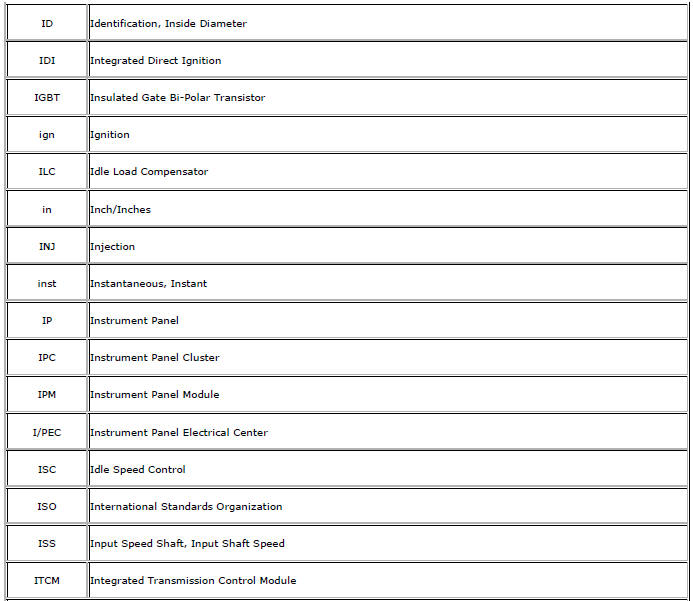

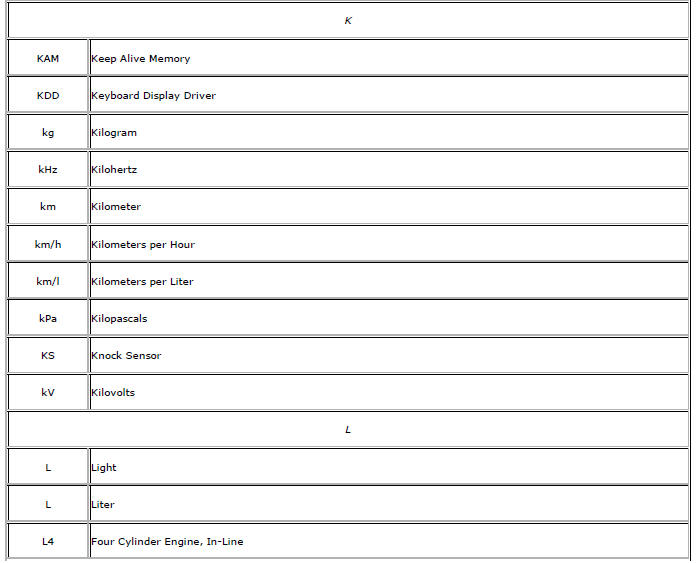

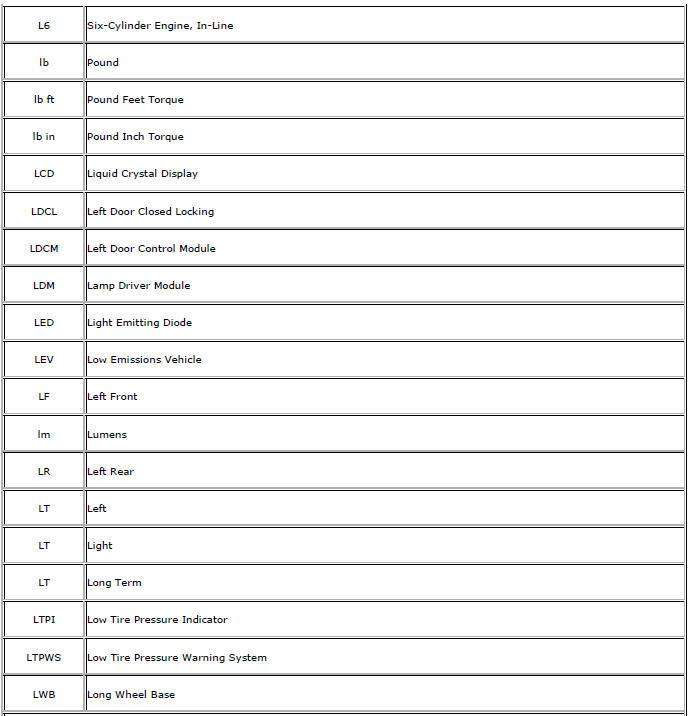

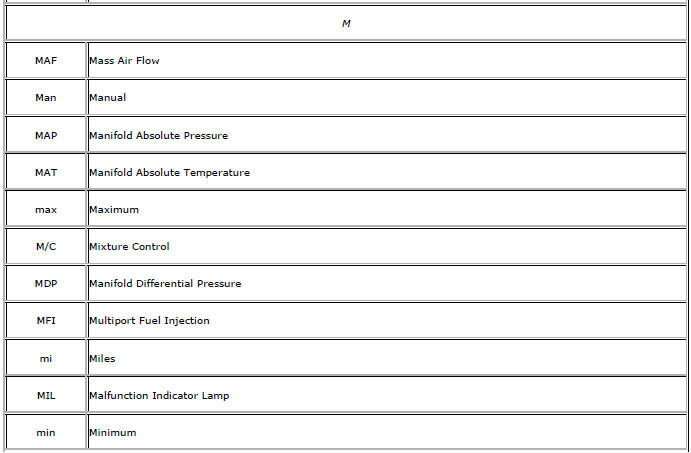

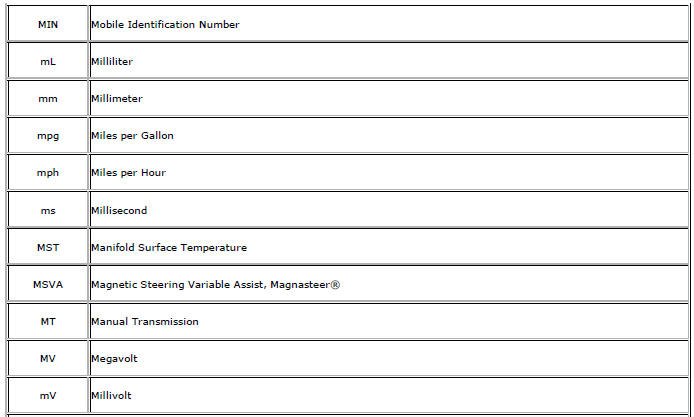

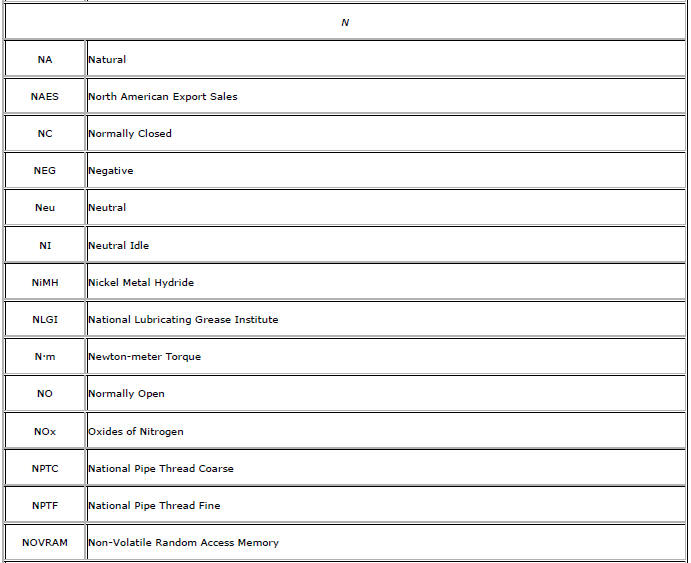

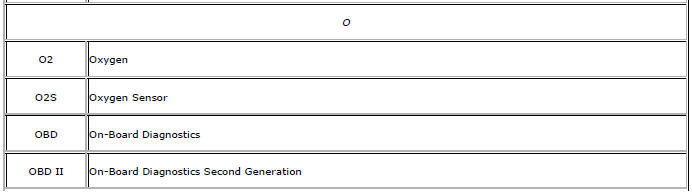

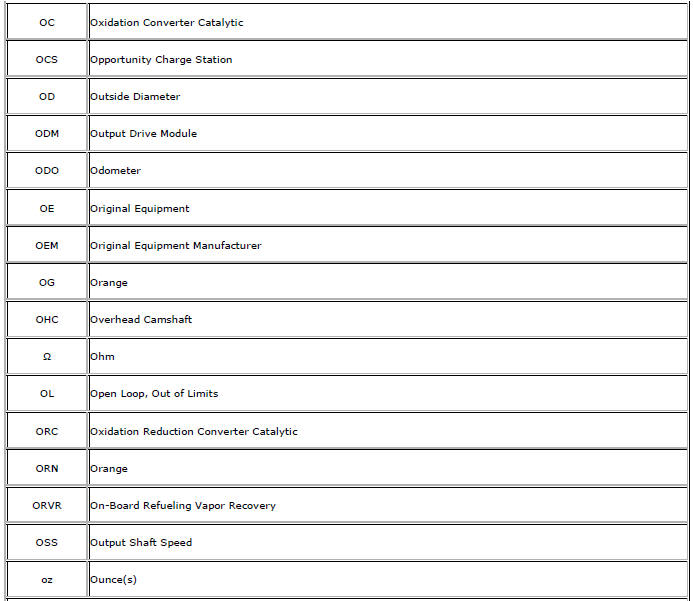

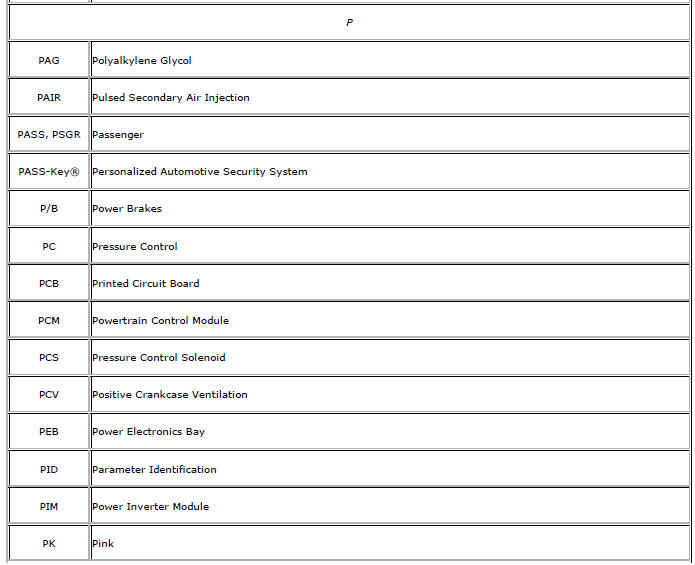

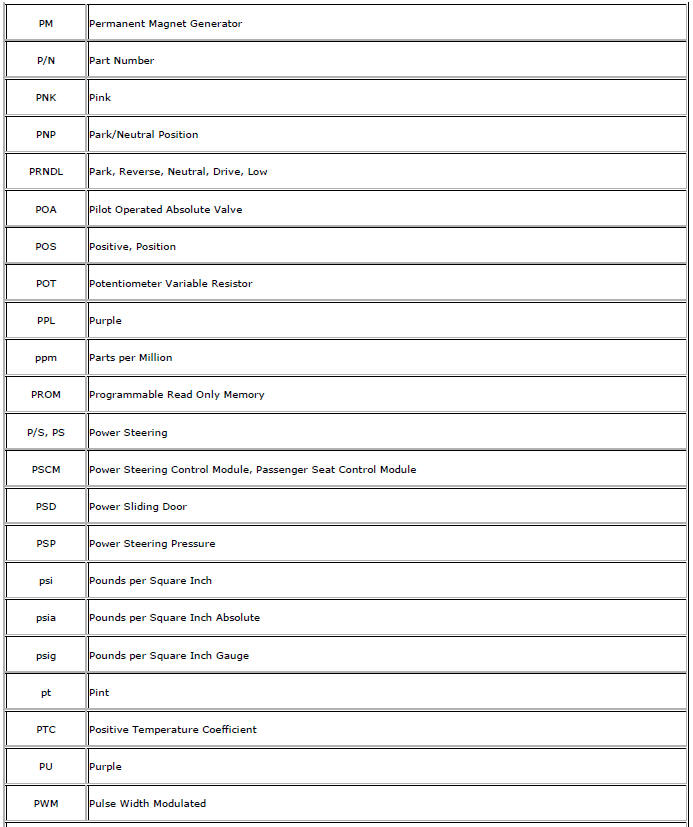

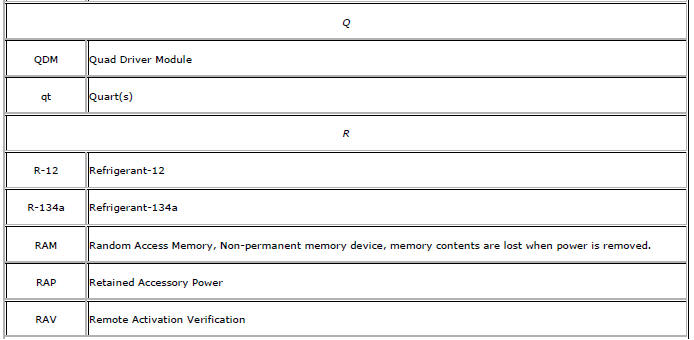

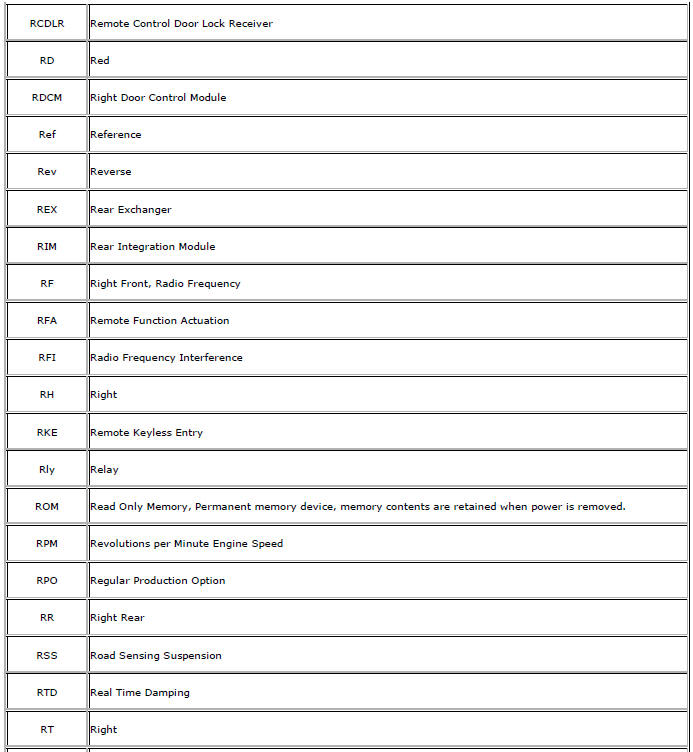

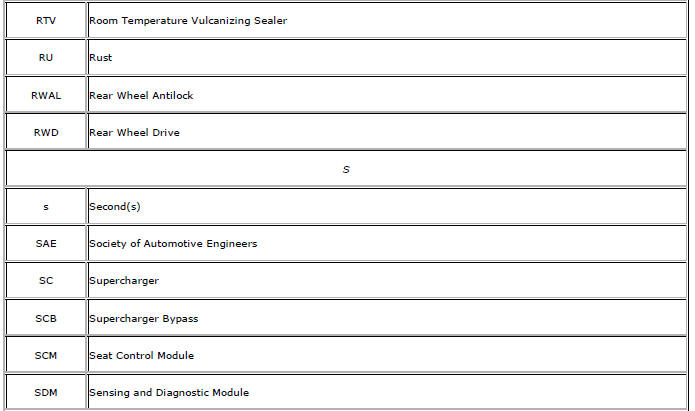

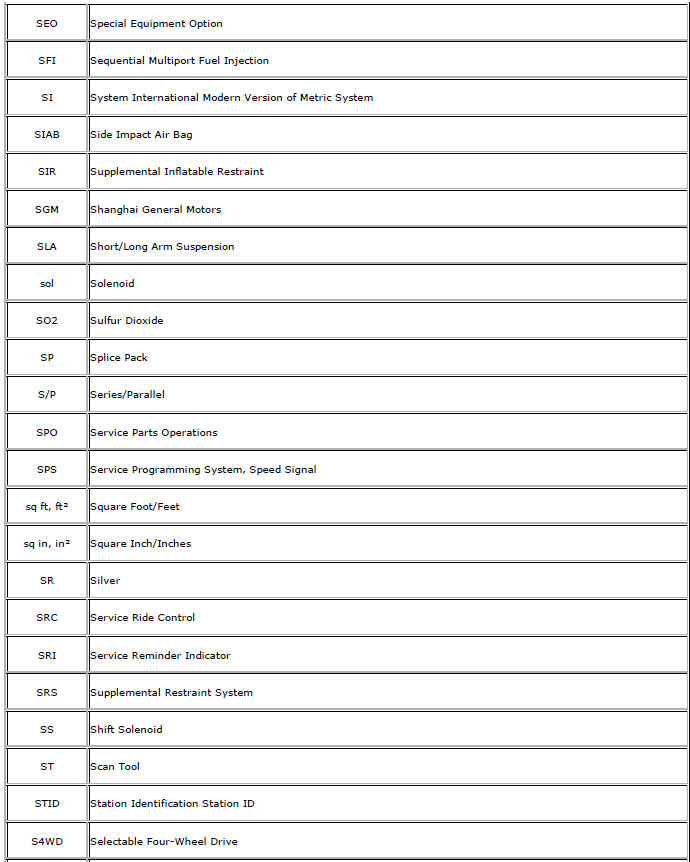

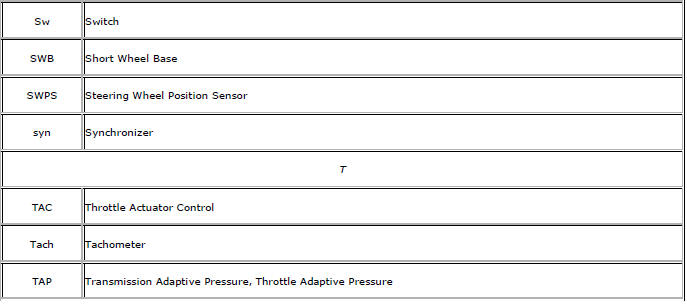

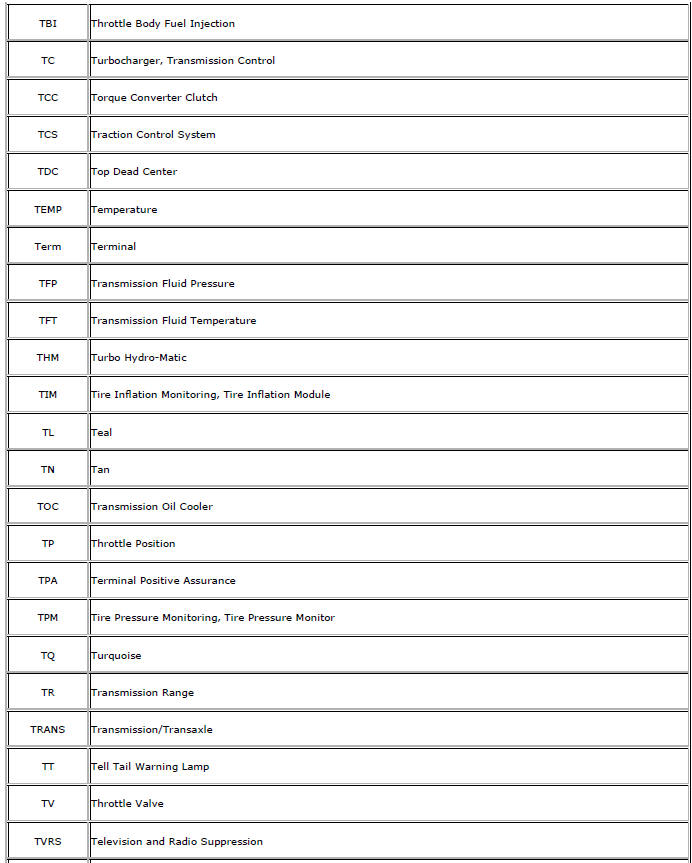

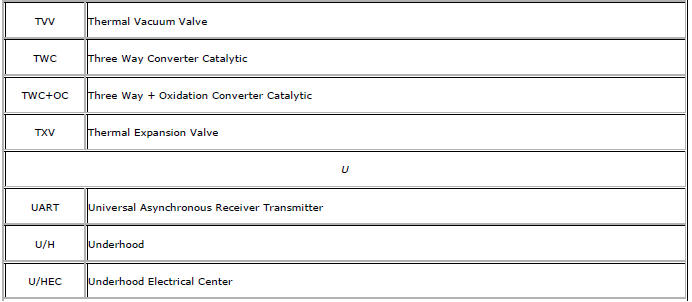

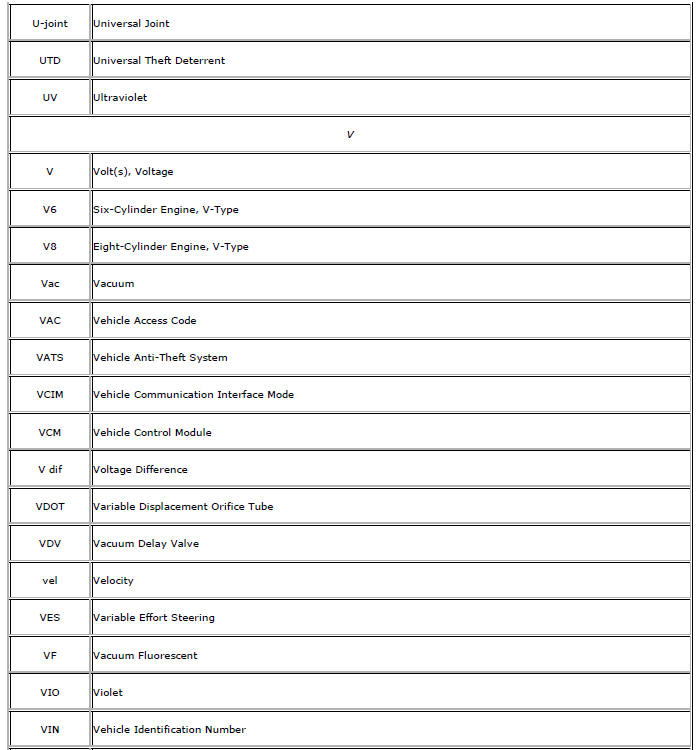

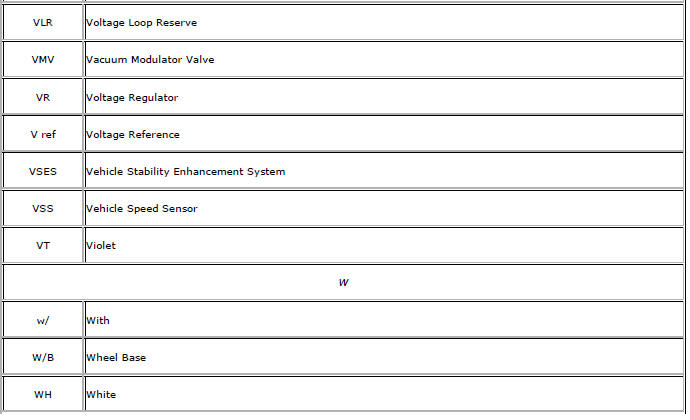

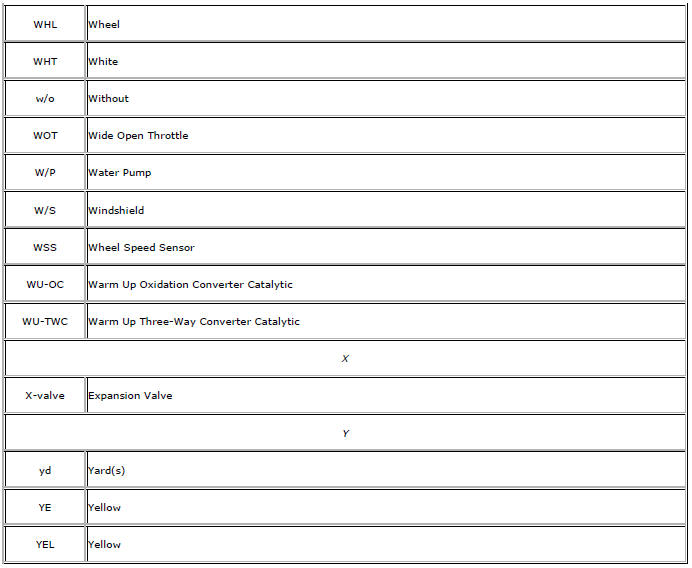

Abbreviations and Meanings

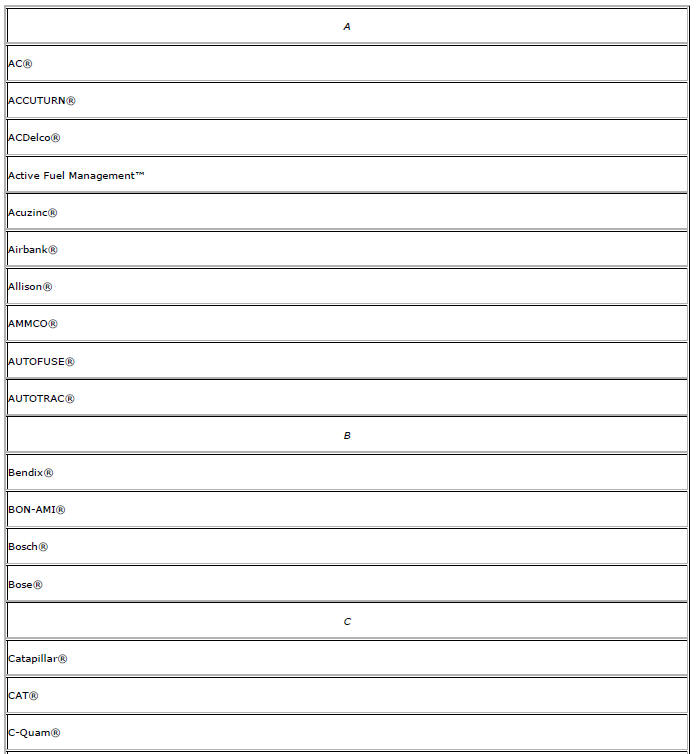

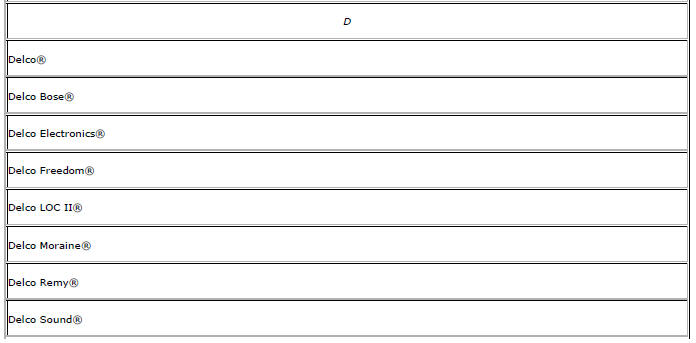

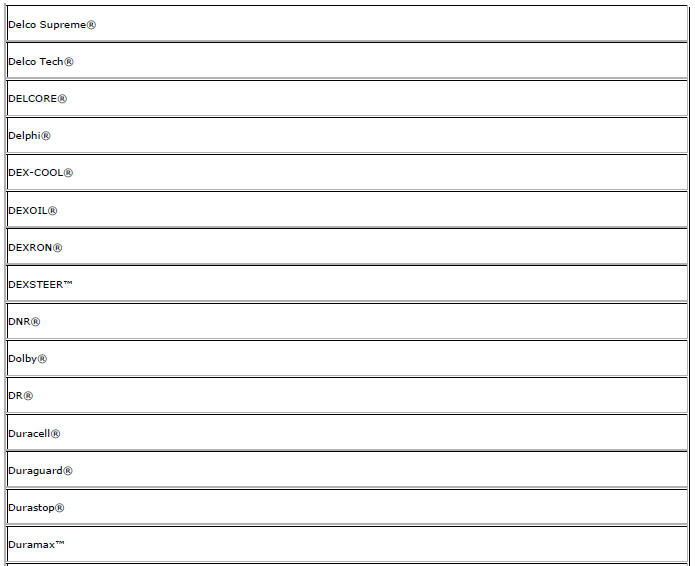

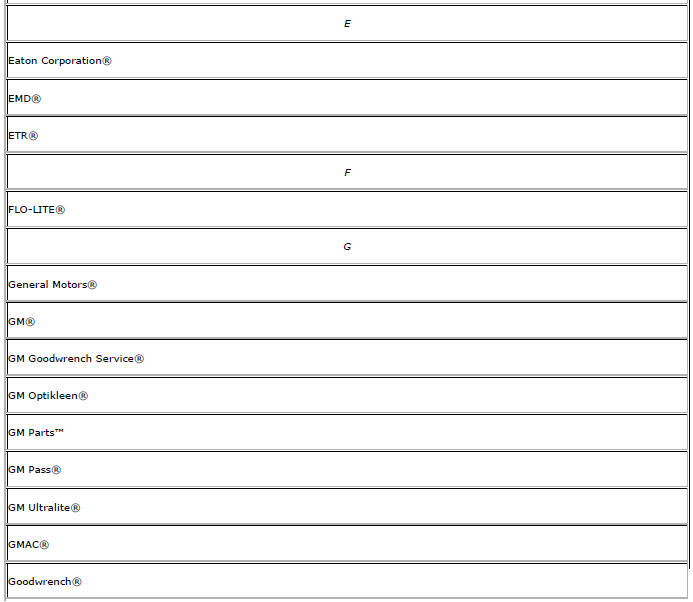

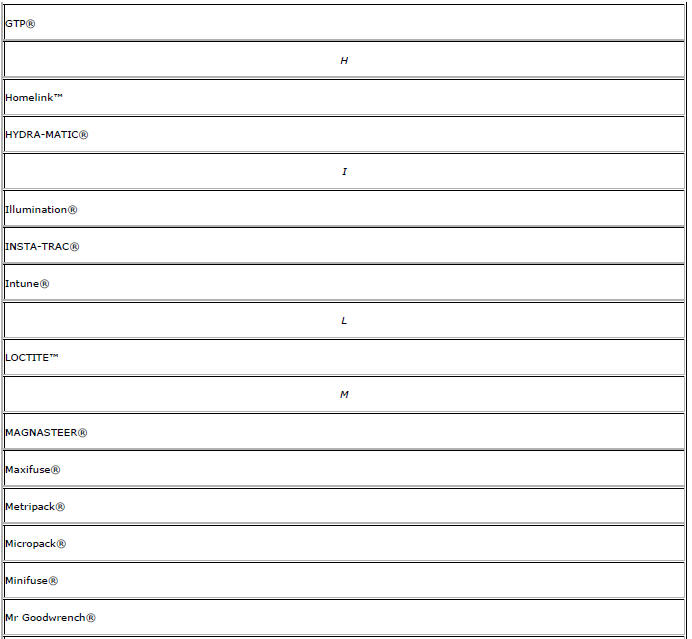

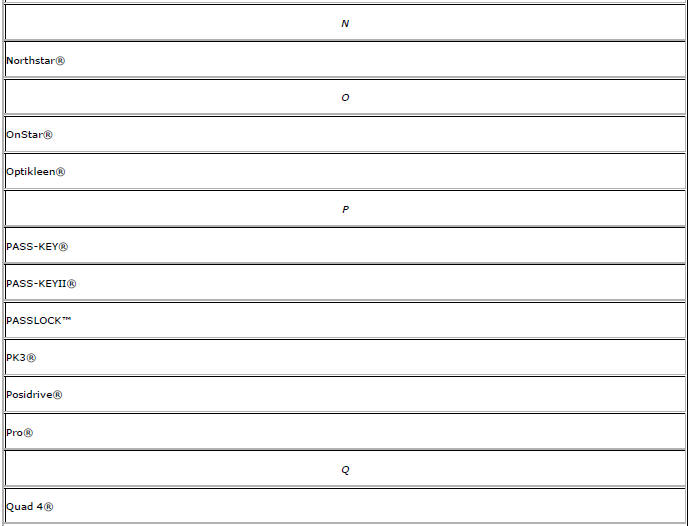

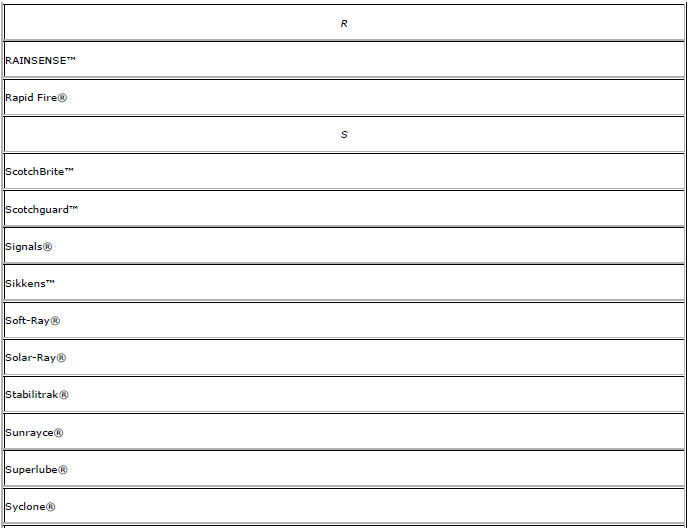

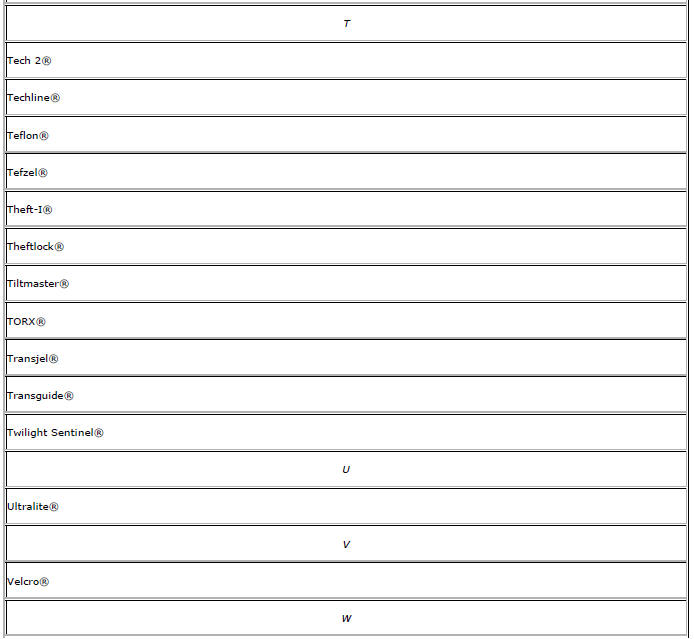

Registered and Non-Registered Trademarks

Listed below are Registered Trademarks (®) or Non-Registered Trademarks (™) which may appear in this service manual.

Prevailing Torque Fasteners

Prevailing Torque Fasteners

Prevailing torque fasteners create a thread interface between the fastener

and the fastener counterpart in order to prevent the fastener

from loosening.

All Metal Prevailing Torque Fasteners

Thes ...

Lifting and Jacking the Vehicle

Lifting and Jacking the Vehicle

Note: The use of a LOW PROFILE LIFT ARMS SYSTEM may be required to

avoid unwanted contact with the vehicle's body and structure

depending on lifting equipment used. Refer to the manufacture's recom ...

Other materials:

Installation Procedure

Install the following components on the drivetrain and front suspension

frame if removed:

The radiator support brackets.

The stabilizer shaft--Refer to Stabilizer Shaft Replacement.

The lower control arms--Refer to Lower Control Arm Replacement.

The steering gear--Refer to Steering ...

Hood Primary Latch Release Cable Replacement

Preliminary Procedure

Remove hood primary latch release cable handle. Refer to Hood Primary

Latch Release Cable Handle Replacement.

Remove the front bumper fascia. Refer to Front Bumper Fascia Replacement

Remove the radiator grille support. Refer to Radiator Grille

Reinforcem ...

New Vehicle Break-In

Notice: The vehicle does not need an elaborate break-in. But it will

perform better in the long run if you follow these guidelines:

• Do not drive at any one constant speed, fast or slow, for the first 805 km (500

mi).

Do not make full-throttle starts. Avoid downshifting to brake or slow the v ...