Chevrolet Cruze Repair Manual: Prevailing Torque Fasteners

Prevailing torque fasteners create a thread interface between the fastener and the fastener counterpart in order to prevent the fastener from loosening.

All Metal Prevailing Torque Fasteners

These fasteners accomplish the thread interface by a designed distortion or deformation in the fastener.

Nylon Interface Prevailing Torque Fasteners

These fasteners accomplish the thread interface by the presence of a nylon material on the fastener threads.

Adhesive Coated Fasteners

These fasteners accomplish the thread interface by the presence of a thread-locking compound on the fastener threads. Refer to the appropriate repair procedure in order to determine if the fastener may be reused and the applicable thread-locking compound to apply to the fastener.

- Prevailing Torque Nut, Center Lock Type

- Prevailing Torque Nut, Top Lock Type

- Prevailing Torque Nut, Nylon Patch Type

- Prevailing Torque Nut, Nylon Washer Insert Type

- Prevailing Torque Nut, Nylon Insert Type

- Prevailing Torque Bolt, Dry Adhesive Coating Type

- Prevailing Torque Bolt, Thread Profile Deformed Type

- Prevailing Torque Bolt, Nylon Strip Type

- Prevailing Torque Bolt, Out-of-Round Thread Area Type

A prevailing torque fastener may be reused ONLY if:

- The fastener and the fastener counterpart are clean and not damaged

- There is no rust on the fastener

- The fastener develops the specified minimum torque against its counterpart prior to the fastener seating

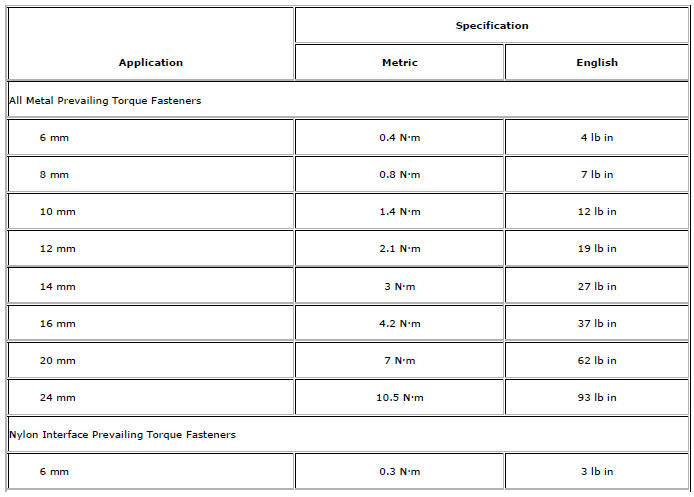

Metric Prevailing Torque Fastener Minimum Torque Development

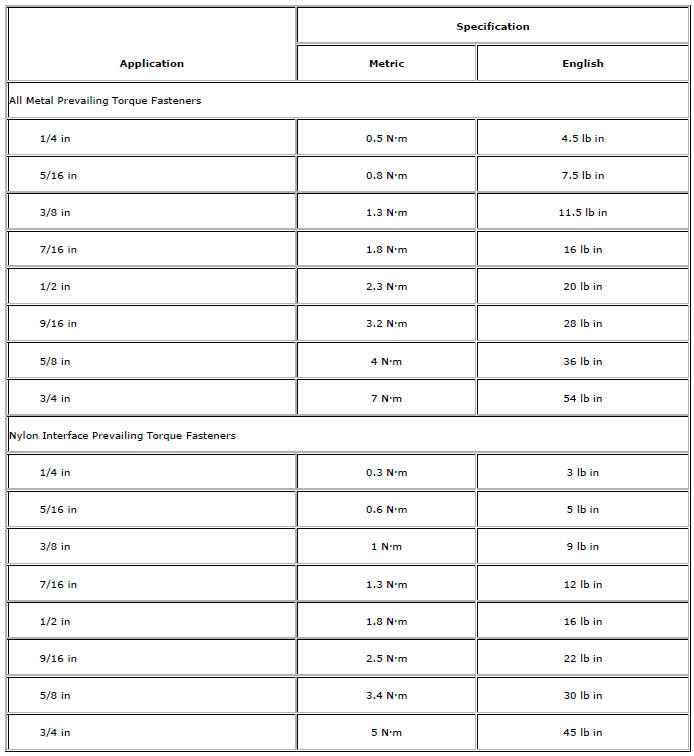

English Prevailing Torque Fastener Minimum Torque Development

Metric Fasteners

Metric Fasteners

This vehicle provides fastener dimensions using the metric system. Most

metric fasteners are approximate in diameter to equivalent

English fasteners. Make replacements using fasteners of the same n ...

Thread Inserts

Thread Inserts

General Purpose Thread Repair Kits.

These kits are available commercially.

Repair Procedure

Warning: Refer to Safety Glasses Warning in the Preface section.

Note: Refer to the thread repair ...

Other materials:

Vehicle Load Limits

It is very important to know how much weight the vehicle can carry. This weight

is called the vehicle capacity weight and includes the weight of all occupants,

cargo, and all nonfactory-installed options.

Two labels on the vehicle show how much weight it may properly carry: the Tire

and Loadi ...

Symbols

The vehicle has components and labels that use symbols instead of text. Symbols

are shown along with the text describing the operation or information relating to

a specific component, control, message, gauge, or indicator.

: This symbol is shown when you need

to see your owner manual for addi ...

Automatic Transmission Fluid

How to Check Automatic Transmission Fluid

It is not necessary to check the transmission fluid level.

A transmission fluid leak is the only reason for fluid loss. If a leak occurs,

take the vehicle to your dealer and have it repaired as soon as possible.

The vehicle is not equipped with a transm ...