Chevrolet Cruze Repair Manual: Removal Procedure

Warning: Refer to Approved Equipment for Collision Repair Warning in the Preface section.

Warning: Refer to Glass and Sheet Metal Handling Warning in the Preface section.

- Disable the SIR System. Refer to SIR Disabling and Enabling.

- Disconnect the negative battery cable. Refer to Battery Negative Cable Disconnection and Connection.

- Remove all related panels and components.

- Visually inspect the damage. Repair as much of the damage as possible.

- Remove the sealers and anti-corrosion materials from the repair area, as necessary. Refer to Anti-Corrosion Treatment and Repair.

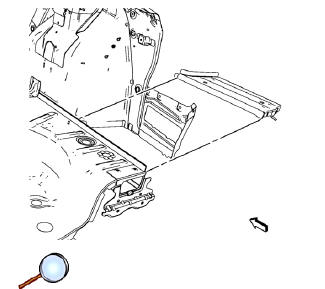

- Locate and mark all the necessary factory welds of the rear floor panel filler.

Note: Note the number and location of welds for installation of the service assembly.

- Drill all factory welds.

- Remove the rear floor panel filler.

Rear Floor Panel Filler Replacement (MIG-Brazing)

Rear Floor Panel Filler Replacement (MIG-Brazing)

Note: According to different corrosion warranties, only the

regional mandatory joining methods are allowed. ...

Installation Procedure

Installation Procedure

Note: If the location of the original plug weld holes can not be

determined, space the braze holes every 40 mm (1½ in).

Create 5 x 18 mm (4/16 x 11/16 in) slots for MIG-brazing along ...

Other materials:

Brake System Warning Light

The vehicle brake system consists of two hydraulic circuits. If one circuit is

not working, the remaining circuit can still work to stop the vehicle. For normal

braking performance, both circuits need to be working.

If the warning light comes on, there is a brake problem. Have the brake system ...

Door Locks

WARNING

Unlocked doors can be dangerous.

Х Passengers, especially children, can easily open the doors and fall out of

a moving vehicle. The chance of being thrown out of the vehicle in a crash is increased

if the doors are not locked. So, all passengers should wear safety belts properly

and ...

Engine Oil Life System

When to Change Engine Oil

This vehicle has a computer system that indicates when to change the engine oil and filter. This is based on a combination of factors which include engine revolutions, engine temperature, and miles driven.

Based on driving conditions, the mileage at which an oil ...